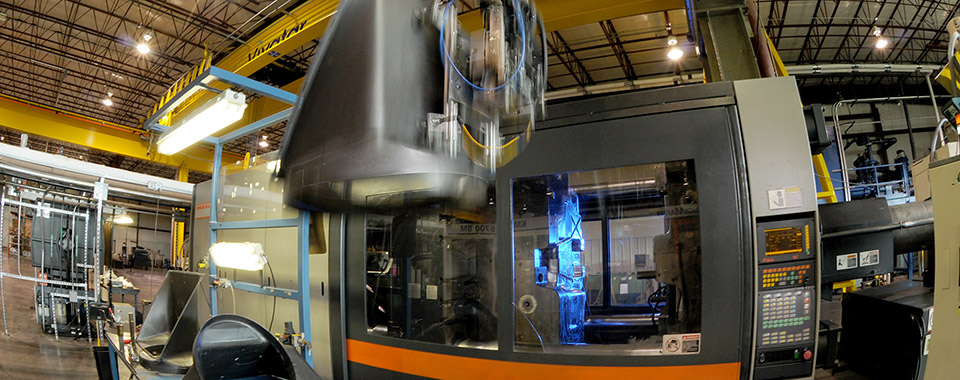

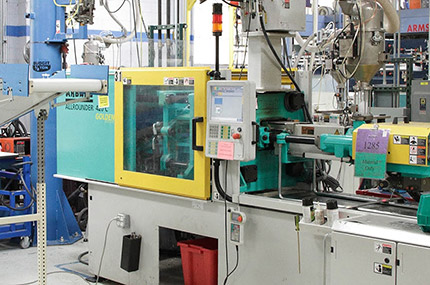

Injection Molding

With over 20 years of molding experience and more than 60 mold machines, KAM Plastics is well equipped to mold just about any kind of plastic product.

- Over 60 molding machines

- 7 to 880 ton

- 3 locations

- Insert molding

- Two-shot molding

- Over-molding

- Robotic load/unload

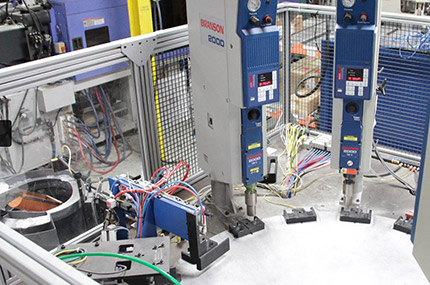

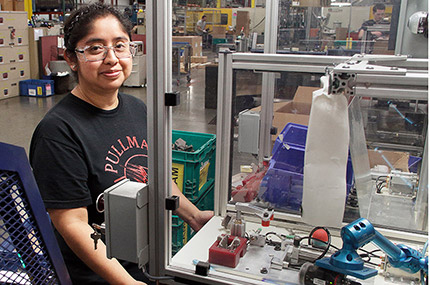

Assembly

We save many of our customers time and money by setting up to do full assembly of products, incorporating our injection-molded parts.

- Electronics integration

- Automated cells

- Sonic welding

- Heat staking

- Optical recognition

- End-of-line testing

Value-Added Processes

KAM plastics collaborates with various supplier partners to integrate value-added process technologies.

- Laser marking

- Painting

- Chrome plating

- Pad printing

- Vacuum metal deposition

Global Shop Solutions ERP

With the Global Shop Solutions Enterprise Resource Planning (ERP) system, KAM Plastics’ manufacturing team accurately schedules resources, outside processes, and material requirements. The accuracy that provides to estimating lead times means better service to KAM Plastics customers.

Every aspect of material needs is tracked, from detailed inventory data to bill-of-material cost build-ups. Managers use the data, often in real time on the shop floor, to accurately predict delivery dates, make efficient purchasing decisions, and measure employee performance.